As the leading manufacturer of tire balancing compounds, we are frequently asked why we do not recommend the use of Counteract Balancing Beads in automotive applications. Typically, when you are using an internal balancing compound, they perform best on vehicles that present a simple or stiff suspension. Therefore, we recommend the use of Counteract in Motorcycles, ATV’s, UTV’s, and any vehicles that present a minimum of a ½ ton suspension.

Unlike some companies that recommend using their compounds in small passenger vehicles, we know from extensive testing, suspension dynamics, and a variety of other elements of physics that you cannot guarantee success or improved performance. Having produced Counteract for over 25 years, and working with large manufacturers and suspension specialists, we have only been able to achieve a 74% success rate in passenger vehicles. From our research and testing, the largest culprit in the passenger vehicle segment that prevents the product from performing at its best is due to the soft suspension of most cars.

Counteract works with two forces to balance out a rotating wheel assembly: Centrifugal Force Inertia. Centrifugal force is the natural force that distributes the beads evenly around the inner liner of the tire, while the Inertia is what positions them where they need to be. This happens when the upward and downward motion of the suspension, and vibrations of the wheel imbalances force the product to do so. As mentioned above, in most cases on a car the suspension is far too soft or is designed differently than that of a heavier vehicle. While the product will still be able to spread around the tire with centrifugal force, it has problems positioning itself quickly due to the false vibrations or lack of vibrations the wheel-end experiences.

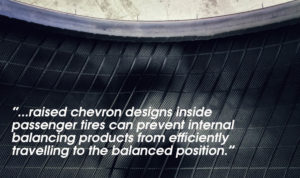

This partnered with the various raised chevron designs inside passenger tires can prevent internal balancing products from efficiently traveling to the balanced position. This will lead to intense vibration, or shimmy until the product can shift to the right position, in some cases it never will. Usually, that vibration will last long enough or become dangerous to the point that the driver will be right back to the tire shop, or the installer. At that point, you have an angry end user, and an angry shop that now must allocate time and free labor to have the wheel balance remedied with traditional wheel weights. This does not look good on any manufacturer, especially when they advertise and market a product for a specific purpose and it does not perform.

This partnered with the various raised chevron designs inside passenger tires can prevent internal balancing products from efficiently traveling to the balanced position. This will lead to intense vibration, or shimmy until the product can shift to the right position, in some cases it never will. Usually, that vibration will last long enough or become dangerous to the point that the driver will be right back to the tire shop, or the installer. At that point, you have an angry end user, and an angry shop that now must allocate time and free labor to have the wheel balance remedied with traditional wheel weights. This does not look good on any manufacturer, especially when they advertise and market a product for a specific purpose and it does not perform.

At Counteract, we know that our reputation depends on the performance of our product. We never want to provide a product that we are not 100% confident in. As the inventor of the world’s top tire balancer, we know where it performs best, and that’s why we’re sticking to those markets. As you can imagine, a 74% success rate sounds pretty good, however, in a market as large as the automotive market, a 26% failure rate is a very large amount of customer complaints that no company can accommodate.