Understanding ST Tires

Not all black circles are the same. There is a reason that tires are categorized for different applications and markets, and it is imperative that consumers understand the reasons why. Understanding what tire should be used and in what application will not only provide the utmost performance of the vehicle, but also the safety of the user and public around them. A large majority of the general public does not understand tires and it is our job, the industry’s job, to provide that education to the people so they can make the correct informed decisions. Or, at the very least, present the consumer with plausible options that they can choose from.

The United States economy is a powerhouse and as the economy continuously gets stronger, so does the demand for specialty trailer tires, aka, special trailer, or ST tires. Many shops and dealers overlook the specialty trailer tire market, but this is a fantastic opportunity to bring in more revenue. The better the economy, the more trailers will be in use. ST imports have risen 12.3% from 2020 (35,671,991 units) to 2021 (40,058,711 units), this is a difference of 4,386,720 tires. This presents some serious momentum, and as the economy continues to repair itself and strengthen, this number is only going to rise. Whether it is a lake-goer who hauls their boat to the cottage, a landscaper hauling loads and equipment to job sites, commercial trucks bringing food to our grocery stores, or that family that hauls a camper trailer – selling and servicing specialty trailer tires opens a lot of opportunity to expand your business and attract new customers.

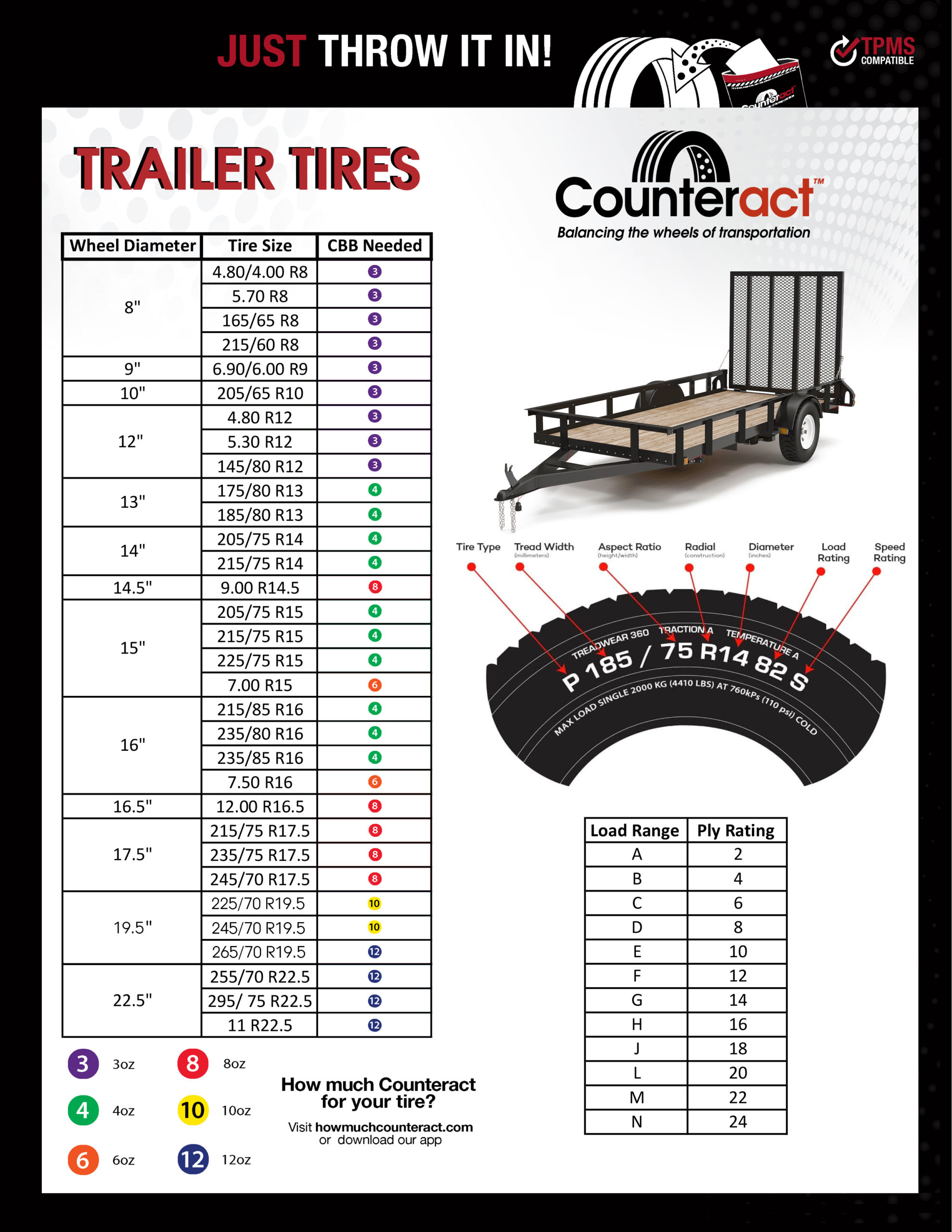

ST tires are built different. They need to be able to withstand a lot of abuse, and specifically be designed to haul heavy loads. Manufacturers construct these tires with extra durability to be stiffer, more puncture resistant, and be able to withstand the elements to include ozone and UV exposures. The main difference between ST tires and your traditional LT or Passenger tire is the ability to handle substantial amounts of weight safely. The more robust the tire, the greater peace of mind the consumer can have when towing their valuables. It is essential for the consumer to know what they are towing and not overload their trailer. This may sound simple, but ST tires come in assorted sizes for various needs, so matching the appropriate tire to the towing application and capacity requirements is critical. Whether someone is towing a boat, car, RV, or recreational equipment, almost all ST tires have a load range that is indicated by a letter system. Most ST tires fall between C (6-ply) to load range G (14-ply), and in some cases even higher. Regardless of load range, ST tires typically have a maximum speed rating of 65mph. These tires are constructed from specific rubber compounds, treads, and bead packages to withstand more abuse than that of a passenger tire. A trailer tire will feature stiffer sidewalls to help stabilize the trailer and prevent the tire from “rolling” under the wheel while making turns, especially at higher speeds. These tires are available in both radial and bias ply options. Radial tires offer higher load requirements often needed for heavy duty or industrial applications, while bias ply tires are often ideal for shorter distance travel or personal use like towing around town.

One thing is certain for ST tires, as for every other tire in use, maintenance is essential. This includes proper tire inflation, regular inspections of the tire to ensure they are wearing properly, and making sure they are properly balanced. Historically, trailer tires are overlooked when it comes to tire balance. As much as inflation is important, the balance of your trailer tires is equally as important. Having a properly balanced trailer tire will not only aid in tire performance, but is essential to providing a smooth ride, control of your trailer and eliminate the possibilities of cargo damage, road damage, and vehicle damage. The best means to balance your trailer tires is not with traditional wheel weights, but rather Counteract Balancing Beads. This is because a traditional wheel weight balance is time consuming, and only balances your wheel and tire at the point of being mounted. Trailers are subject to a lot of abuse, they sit for extended periods of time, are towed through rough terrain, and are frequently neglected rendering traditional balancing techniques obsolete. As that tire endures its journey and experiences changing conditions, wheel weights cannot adjust their position as the balance of that tire changes. Wheel weights will also fall off, making the wheel unbalanced and contaminating the environment. By using Counteract, it is placed inside the tire as it is being mounted and will not only balance the wheel and tire, but everything rotating off the axle end. This includes the wheel, tire, hub, and brake drum/disc while being able to adjust and change its position inside the tire as needed to provide the best balance possible on the fly.

Additionally, most trailers are not used as often as a passenger vehicle, so it is not unusual for a ST tire to age out before it wears out. What this means is that the tire itself may still have sufficient tread depth, but the sidewalls of the tires may exhibit excessive cracking from ozone and UV exposure. At this point, no questions should be asked, if cracking is evident, so is replacing those tires. Time, elements, and storage conditions are all reasons a tire can weaken even if it appears visually robust. However, since ST tires support a lot of weight even when not in use, these situations can damage the structure of the tire.