It is a well-known fact that an unbalanced wheel assembly will lead to premature tire wear. One common example is river wear caused by the slope in the road and imbalanced wheel assemblies. This premature wear can reduce the tire life by up to 50%.

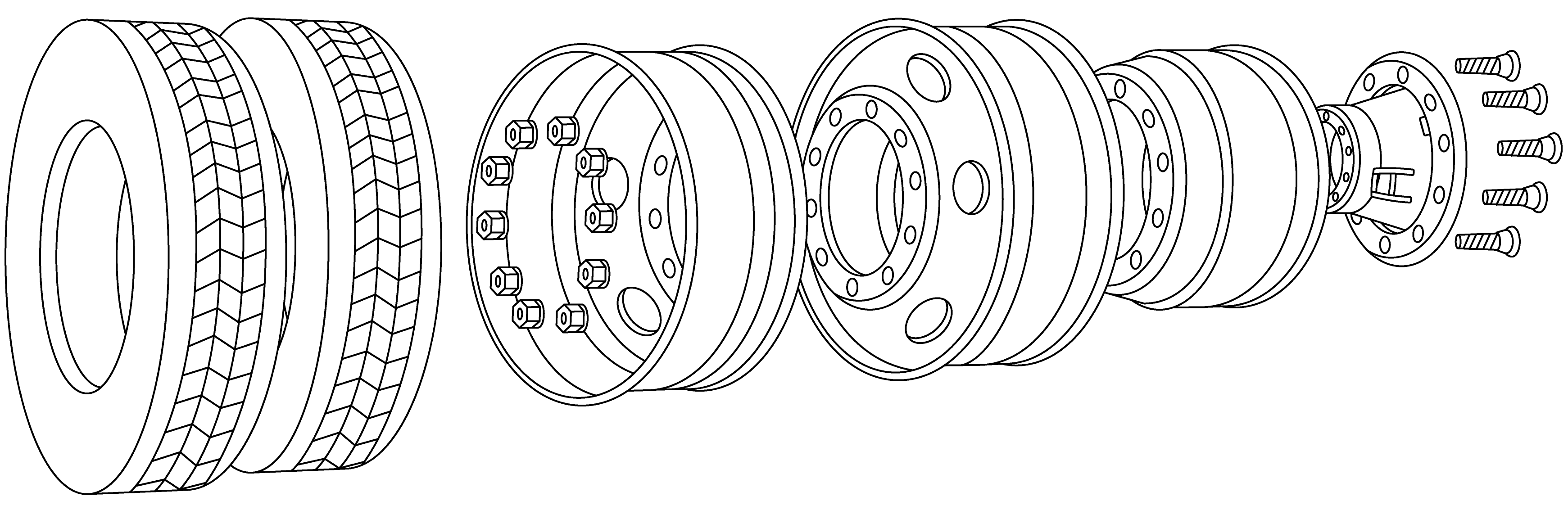

Despite advances in tire technology, commercial truck wheel assemblies range between 6-8oz out of balance, which can cause significant problems. At highway speeds, this 6oz amplifies to 60lbs due to centrifugal force alone. This is equivalent to hitting your tire with a sledgehammer with every rotation. However, the real problem occurs at highway speeds when the tires heavy spot rotates up and down at the same frequency of the rebound frequency of the suspension. When these two frequencies join, they create a force strong enough to lift a 10-ton axle up and down. This causes immense strain on the tire, leading to heat buildup, increased friction with the road surface, as well as stress on the driver and vehicle components. Since the tire is not achieving a consistent footprint with the road surface, segments of the tire wear prematurely, creating river wear or depression wear, reducing the life of the tire by up to 50%. Counteract was the first to explain this overlooked occurrence to the tire industry. To prevent this, it is essential to balance the entire axle end of the wheel assembly, including all moving parts, rather than just balancing the tire and wheel.

Unfortunately, the trucking industry was not aware of a solution to this whole problem and was only focusing on the tire and wheel, not the complete wheel assembly. By balancing just half of the wheel assembly, they were addressing only a portion of the problem. For years it was almost impossible to balance every element in the rotating axle end. This led to billions of dollars in losses every year. Most commercial vehicles on the road today only have their steer tires balanced. Counteract is the most cost-effective, proven solution to this problem. On average, using Counteract can increase tire life by a minimum of 30%, which can result in billions of dollars in savings for the industry. With a commercial tire averaging around 300 dollars and 30 million tires sold annually, a 30% increase in tire life would equate to almost 2.7 billion dollars in savings simply by throwing a bag of Counteract in every tire. Counteract has even received countless testimonials from first-time customers who have doubled their tire life.

Furthermore, Counteract has undergone three independent fuel economy tests, all with successful results. Counteract was aware it took energy to wear tires prematurely and knew that energy consumption would come from the fuel. Counteract is the only balancing method to prove fuel economy savings through the industry-standard test, the SAE J1321 and TMC RP-1102 Type II fuel test by balancing the complete wheel assembly. With a proven savings of 2.2% the potential fuel savings to the trucking industry would be roughly 3 billion dollars annually. A MVTS-certified fuel economy test was performed with partially filled water containers as weights and studied on a rough, previously abandoned track. This showed no improvement in fuel economy and proved that road conditions and cargo do impact rolling resistance. These tests were a shock to the industry as Counteract has been the only ones to show that balancing the complete wheel assembly is necessary.

Competitors have used Counteract’s test results to promote balance-related fuel savings, but they have not been able to replicate the same results. This is because Counteract has spent years perfecting their internal balancers, including the materials used, recommended amounts, and quality control processes. The results were not received well in the industry as they went against everything previously marketed before these results were made public.

Using Counteract not only saves the industry money in fuel and tires, but it also has proven to reduce tire operating temperature, prolonging tire casing life as excess heat is the number one enemy of tires. A heat test done at the University of Brazil showed that Counteract kept the tire running 30 degrees cooler compared to tires that were not balanced, and surprisingly 63 degrees cooler compared to a competitive product.

It is no wonder that Counteract is the number one tire balancer in the industry, balancing millions of tires every year without ever recording a single warranty issue. Counteract goes above and beyond to provide the best method of balancing the industry can offer, and the tests to prove it. With extended tire life, improved fuel economy, and reduced tire maintenance, it is safe to say that the industry could save billions by simply balancing the complete axle end using Counteract Balancing Beads. Counteract has proven to be the experts when it comes to balancing. Over the years, Counteract has developed many other wheel solutions and continues to be an industry leader.