Enhancing Vehicle Safety through Proper Lug Nut Torquing

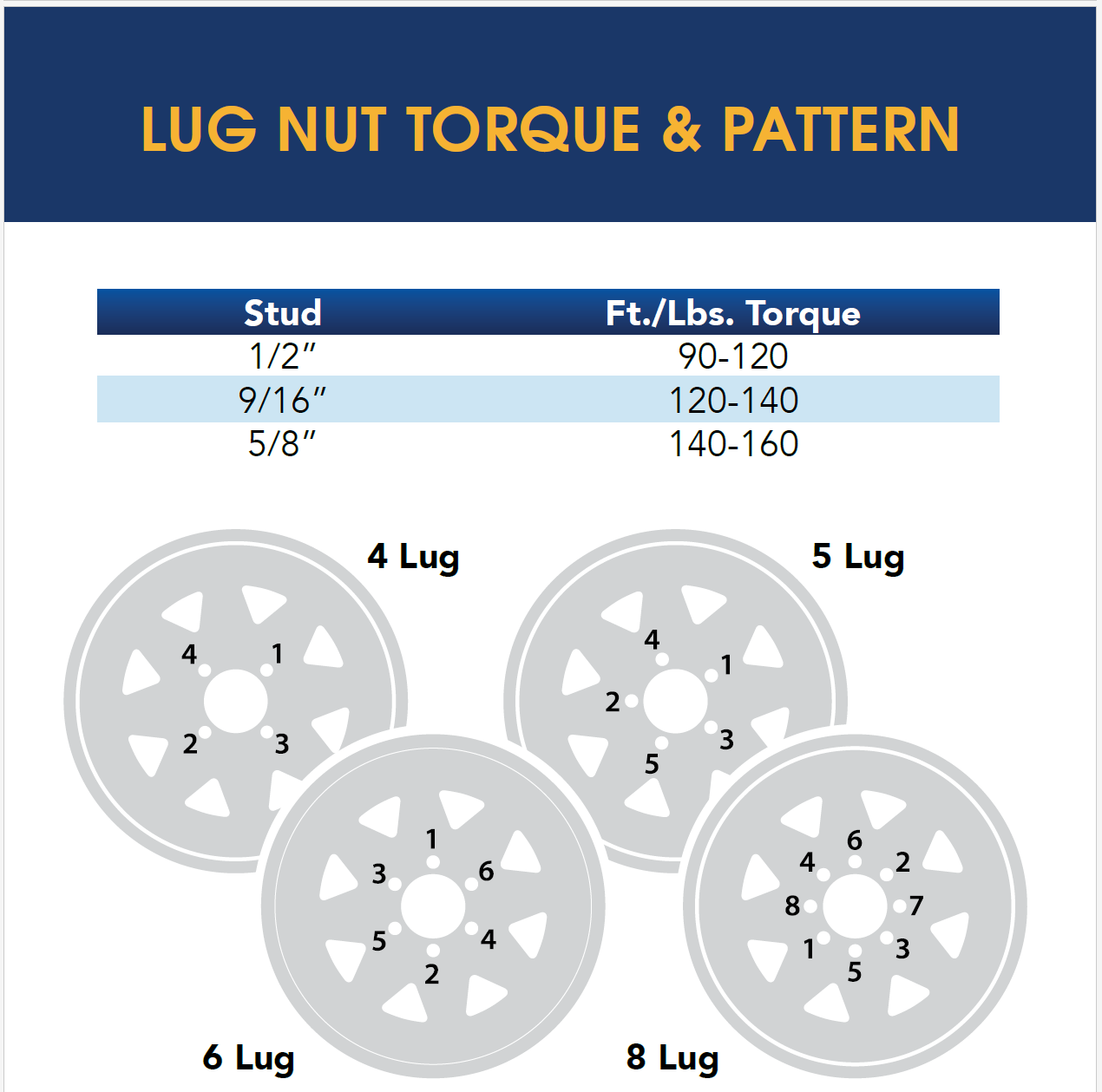

Torque sequence, the specific pattern in which lug nuts are tightened, plays a crucial role in preventing wheel-related mishaps and mechanical failures. In response to the risks associated with wheels coming off, industry leaders have introduced essential practices to maintain the safety of vehicles post-mechanic visits. Emphasizing the correct application of torque to lug nuts is imperative in averting wheel detachment.

The Risks of Incorrect Torquing

Utilizing a torque-measuring instrument is vital, as over-torquing can lead to adverse consequences such as stretched studs, snapped components, or nuts remaining loose and potentially threading off while the vehicle is in motion. Achieving the right balance in torque is essential for both safety and the longevity of wheel components.

Addressing Challenges During the Mounting Process

During wheel mounting, the mating surface of the wheel and the hub face may not align perfectly due to the wheel’s weight exerting pressure on the studs and hub. Mechanics often need to apply pressure at the top and bottom of the wheel to ensure a flush fit with the hub. Failing to address this issue properly can result in uneven torquing and compromise the safety of the wheel.

The Role of Torque Sequence in Preventing Uneven Torquing

The torque sequence is designed to eliminate the risk of uneven torquing during the lug nut tightening process. When lug nuts are torqued in a clockwise pattern without considering the sequence, there is a potential for the wheel to become more flush as the process progresses. This can create space between the nut and wheel, leading to lug nuts not being torqued to specifications, thereby increasing the risk of a wheel detachment.

Ensuring Even Torque Distribution for Wheel Safety

Implementing a torque sequence ensures that torque is evenly applied to opposing lug nuts, promoting early flush contact with the wheel. This proactive approach mitigates the possibility of uneven torquing and provides assurance that all lug nuts are tightened to specifications, significantly reducing the risk of a wheel detachment incident. Understanding and adhering to torque sequence guidelines is paramount for maintaining the safety and reliability of vehicles.

Counteract Socket Pro

Discover the efficiency of Counteract’s Socket Pro as it demonstrates the correct torque pattern in commercial truck wheels. Click the link to watch the informative video, gaining valuable insights into lug nut torquing. https://counteractbalancing.com/socketpro/