When it comes to ensuring the safety and performance of commercial trucks, the choice between drum brakes and disc brakes plays a pivotal role. Each braking system comes with its own set of advantages and disadvantages, making the decision a crucial one for fleet managers and truck operators.

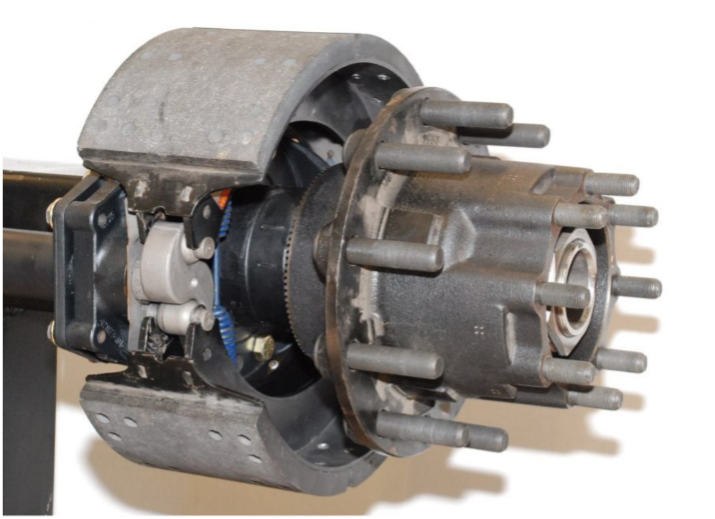

Pros of Commercial Truck Drum Brakes:

1. Cost-Effective Maintenance:

-

- Drum brakes are generally more cost-effective to maintain and replace. The parts are often less expensive, and the simplicity of the design makes them easier to service.

2. Heat Dissipation:

-

- Drum brakes have a larger surface area, which allows for better heat dissipation during braking. This can be beneficial for long descents or situations that require extended braking periods.

3. Durability:

-

- Drum brakes are known for their robustness and ability to withstand harsh conditions. They are less exposed to environmental elements, reducing the risk of corrosion and wear.

4. Parking Brake Functionality:

-

- Drum brakes are commonly used for parking brake applications, providing an additional layer of safety when the truck is parked.

Cons of Commercial Truck Drum Brakes:

1. Weight:

-

- Drum brakes are generally heavier than disc brakes, contributing to increased overall vehicle weight. This can affect fuel efficiency and payload capacity.

2. Heat Dissipation Limitations:

-

- While drum brakes have good heat dissipation, they may be prone to overheating in high-demand situations, potentially leading to brake fade and reduced performance.

___________________________________________________________________________________________________________________

___________________________________________________________________________________________________________________

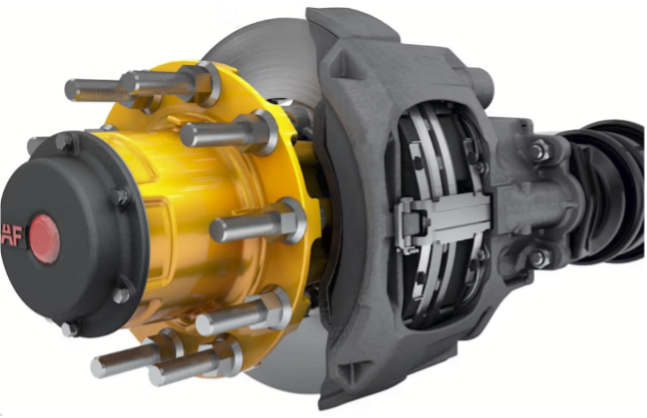

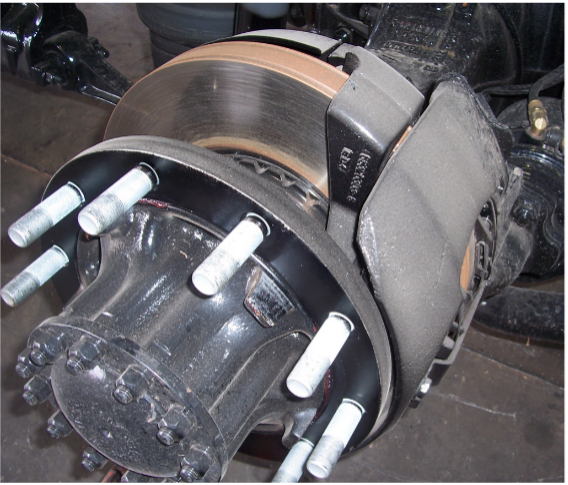

Pros of Commercial Truck Disc Brakes:

1. Improved Stopping Power:

-

- Disc brakes offer superior stopping power, particularly in emergency situations. This can be crucial for the safety of the driver, cargo, and other road users.

2. Better Heat Dissipation:

-

- Disc brakes dissipate heat more efficiently due to their open design. This makes them well-suited for heavy-duty applications, reducing the risk of brake fade.

3. Reduced Weight:

-

- Disc brakes are generally lighter than drum brakes, contributing to overall weight reduction and potential improvements in fuel efficiency.

4. Ease of Inspection:

-

- Disc brakes are easier to inspect visually, allowing for quicker and more straightforward maintenance checks.

Cons of Commercial Truck Disc Brakes:

1. Higher Initial Cost:

-

- The upfront cost of disc brakes is typically higher than that of drum brakes. However, some argue that the long-term benefits may outweigh the initial investment.

2. Maintenance Complexity:

-

- Disc brakes can be more complex to service, and replacement parts may be more expensive compared to drum brakes.

The choice between commercial truck drum brakes and disc brakes ultimately depends on various factors, including the truck’s application, operating conditions, and budget considerations. Fleet managers must carefully weigh the pros and cons of each braking system to make informed decisions that prioritize both safety and cost-effectiveness on the road.

The choice between commercial truck drum brakes and disc brakes ultimately depends on various factors, including the truck’s application, operating conditions, and budget considerations. Fleet managers must carefully weigh the pros and cons of each braking system to make informed decisions that prioritize both safety and cost-effectiveness on the road.