Valve stems are essential components in automotive wheels, responsible for maintaining proper tire inflation and ensuring safety on the road. While their basic function remains the same across different materials, the choice between rubber, aluminum, and brass valve stems can significantly impact performance, durability, and maintenance requirements. Let’s delve into the characteristics, applications, and pros and cons of each type.

_______________________________________________________________________________________________________________________

Rubber Valve Stems

Description: Rubber valve stems are typically made from synthetic rubber compounds and are flexible yet durable.

Applications: They are commonly found in standard passenger vehicles, motorcycles, and bicycles.

Pros:

- Flexibility: Rubber valve stems can flex with the tire movement, reducing the risk of damage from vibrations and impacts.

- Cost-effective: They are generally more affordable than metal valve stems, making them a popular choice for budget-conscious consumers.

- Ease of Replacement: Rubber valve stems are relatively easy to replace during tire maintenance or repairs.

Cons:

- Durability: Compared to metal valve stems, rubber ones may wear out faster, especially in harsh environments or with heavy-duty use. They also tend to be more susceptible to UV deterioration over time.

- Pressure Limitations: They may not be suitable for high-pressure applications, such as in racing or high-performance vehicles.

_______________________________________________________________________________________________________________________

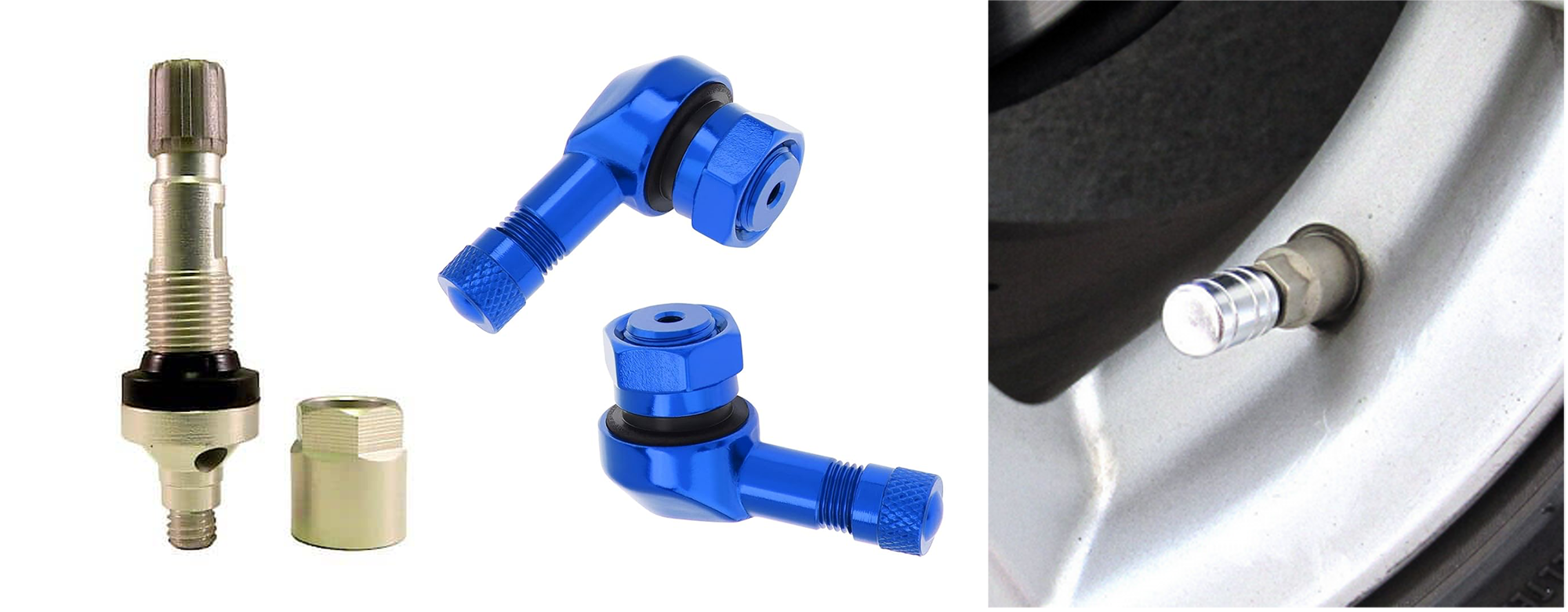

Aluminum Valve Stems

Description: Aluminum valve stems are lightweight yet strong and machined from solid aluminum alloy.

Applications: They are used in some standard passenger car applications presenting TPMS, many performance vehicles, racing cars, and motorcycles where weight reduction and durability are crucial.

Pros:

- Lightweight: Aluminum valve stems contribute to reducing unsprung weight, enhancing vehicle handling and performance.

- Durability: They are more resistant to corrosion and wear compared to rubber valve stems, especially in challenging conditions.

- Aesthetic Appeal: Aluminum valve stems can be an aesthetic upgrade, available in various finishes to match wheel designs.

Cons:

- Cost: They tend to be more expensive than rubber valve stems, which can impact overall maintenance costs.

- Potential for Damage: Aluminum valve stems can be susceptible to damage from impacts or bending, requiring careful handling.

_______________________________________________________________________________________________________________________

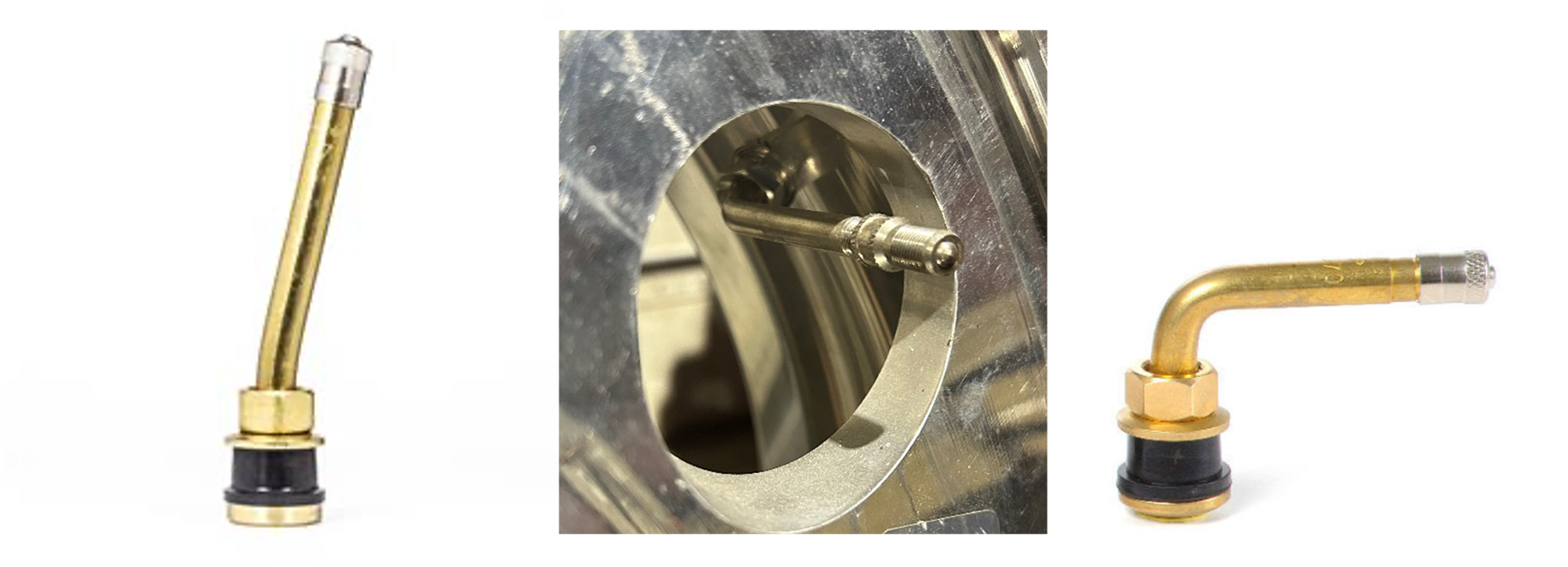

Brass Valve Stems

Description: Brass valve stems are made from a durable alloy of copper and zinc, known for their strength and corrosion resistance.

Applications: They are commonly used in heavy-duty vehicles, busses, commercial trucks, and industrial equipment.

Pros:

- Strength: Brass valve stems are robust and capable of withstanding high pressures and heavy loads.

- Corrosion Resistance: They are highly resistant to corrosion, making them suitable for long-term use in various weather conditions.

- Reliability: Brass valve stems offer reliable performance, crucial for commercial and industrial applications where downtime must be minimized.

Cons:

- Weight: Brass valve stems are heavier compared to aluminum and rubber counterparts, which may not be ideal for applications where weight reduction is critical.

- Cost: They can be more expensive than rubber valve stems, though generally less costly than aluminum ones.

_______________________________________________________________________________________________________________________

Choosing the Right Valve Stem

Selecting the appropriate valve stem for your vehicle depends on factors such as intended use, environmental conditions, and budget considerations. For standard passenger vehicles, rubber valve stems provide a cost-effective solution. In contrast, aluminum valve stems are preferred for performance vehicles due to their lightweight and durability. Brass valve stems excel in heavy-duty applications where strength, high tire pressure and reliability are paramount.

Regular inspection and maintenance of valve stems are essential to ensure proper tire inflation and safety on the road. Whether you’re a weekend driver, a racing enthusiast, or a commercial fleet operator, understanding the differences and advantages of each type of valve stem will help you make informed decisions to optimize vehicle performance and longevity.