In the world of commercial trucking, uptime is everything, and downtime can be a death sentence. Whether you’re hauling freight across provinces or states, or operating a local delivery fleet, every mile matters. Every problem under the chassis can become a costly one. One of the most overlooked causes of wear, fuel inefficiency, and premature component failure is wheel and tire imbalance.

While it may seem minor compared to engine or brake issues, imbalanced tires have a massive cumulative impact on the bottom line of commercial operations. We’ll break down the true costs of tire imbalance, signs to watch for, and why proper balancing is an investment, not an expense.

While it may seem minor compared to engine or brake issues, imbalanced tires have a massive cumulative impact on the bottom line of commercial operations. We’ll break down the true costs of tire imbalance, signs to watch for, and why proper balancing is an investment, not an expense.

What Is Tire Imbalance?

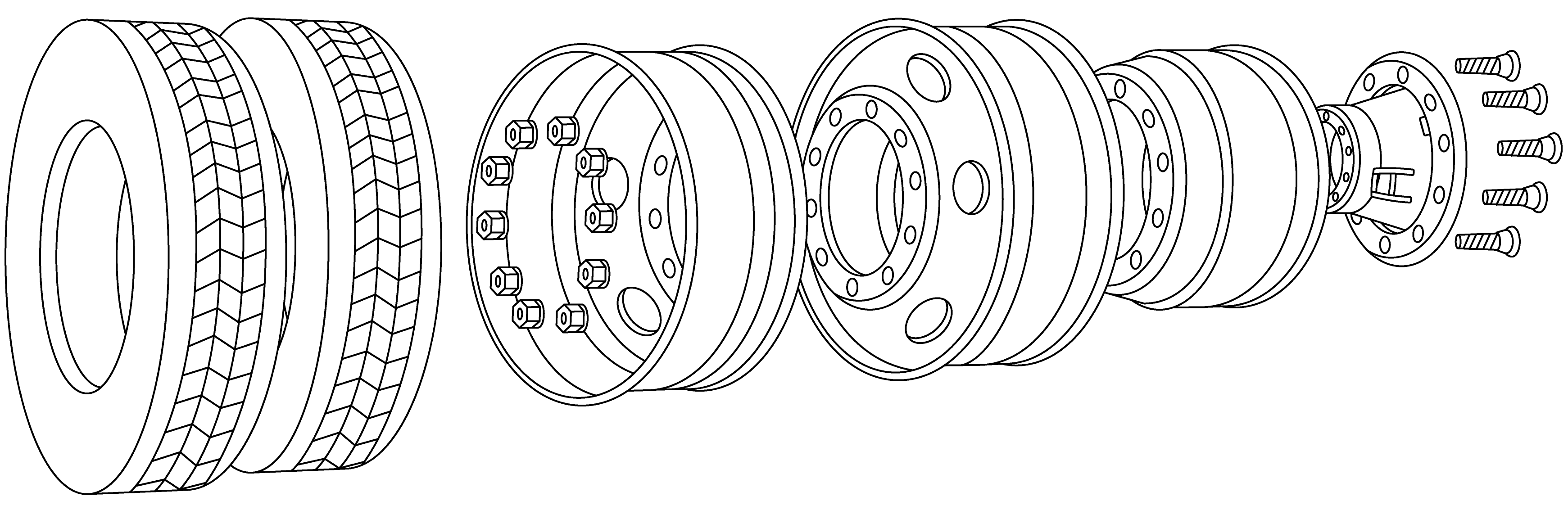

Tire imbalance occurs when the mass of a tire and wheel assembly is not evenly distributed around the axle. This creates a wobble or vibration as the wheel turns, and the heavier the vehicle, the greater the consequences.

Unlike passenger vehicles, commercial trucks have:

- More wheel positions (typically 18 wheels or more)

- Heavier loads

- Longer hours on the road

- More sensitive alignment and suspension systems

All of this amplifies the effects of imbalance.

The Real-World Costs of Imbalanced Truck Tires

1. Accelerated Tire Wear

- Up to 20% reduction in tire life has been documented when tires are left unbalanced.

- Uneven wear leads to flat spotting, scalloping, and blowouts which are particularly dangerous on steer tires.

- For a fleet running premium tires, this could mean losing thousands per vehicle in premature replacements.

2. Suspension and Steering Component Damage

Vibrations caused by imbalance put constant stress on the wheel, tire, tie rods, shocks, bearings and kingpins. Over time, this leads to component failure, downtime, and costly repairs. Not to mention, alignment issues that further compound the wear.

3. Increased Fuel Consumption

- Imbalanced tires cause rolling resistance and vibration, forcing the engine to work harder.

- A 2–3% drop in fuel efficiency is not uncommon.

- At current fuel prices, that can mean $1,000–$2,000+ in wasted fuel per truck, per year especially for long-haul fleets.

4. Driver Fatigue and Safety Risk

- Constant vibration through the steering wheel and cab creates fatigue and distraction.

- This increases the risk of accidents and DOT violations.

- Poor ride quality is also a factor in driver retention — and good drivers are hard to keep.

How to Spot Imbalanced Tires on a Commercial Vehicle

Watch for:

- Steering wheel vibration at certain speeds, typically highway speeds

- Uneven tread wear (especially cupping on steer tires)

- Premature shock absorber wear

- Noises or “hopping” feeling at highway speeds

- Increased driver complaints about ride quality

Many of these signs are gradual, so routine inspection and balancing should be part of a proactive maintenance plan.

Static vs. Dynamic Balancing: What Works Best for Trucks?

Many commercial shops still use static spin balancers, which rely on physical weights attached to the outside of the wheel to correct imbalances. While useful, they don’t account for real-world conditions like tire wear, load shift, or changes in road force. You would need to frequently be monitoring your tires and re-balancing as needed which is time consuming and labor intensive.

Internal tire balancing, using products like Counteract Balancing Beads, offers a smarter, ongoing solution.

Why IBA’s (Internal Balancing Agents) is a Smart Investment

Counteract moves with the tire as it rotates, redistributing themselves in real time to counteract imbalance caused by load, speed, and wear. A significant and often overlooked benefit is Counteract balances not only the wheel and tire, but the entire wheel assembly. By doing so and having the ability to adjust its position when needed, Counteract provides a superior, more efficient continuous complete wheel assembly balance for the life of the tire.

Key benefits of Counteract:

- Self-adjusting balance over the life of the tire

- Eliminates the need for rebalancing

- Reduces irregular wear on steer and drive tires

- Protects suspension components and minimizes maintenance

- Proven to improve fuel economy by 2.2% in two independently run SAE J1321/TMC RP-1102 Type II fuel tests.

- Average tire life increase of 33%+

- Only balancing product that is proven through multiple 3rd party tests to be safe for TPMS systems and sensors

Real-World Example

A regional fleet of 20 trucks reported:

- 25% increase in steer tire life after switching to IBA balancing

- Over $18,000/year saved on tire replacements alone

- Fewer alignment corrections, premature tire replacements and improved driver satisfaction

In an industry where every mile counts, tire imbalance is not just a comfort issue, it’s a profitability issue. Commercial trucks carry heavier loads, travel longer distances, and have far more to lose when tire balance is neglected, and unfortunately, in the commercial truck industry it is very common to not balance tires at all.

However, incorporating a proper tire balancing program, or process, especially with an IBA like Counteract into your maintenance strategy isn’t just smart. It’s essential.